LSM

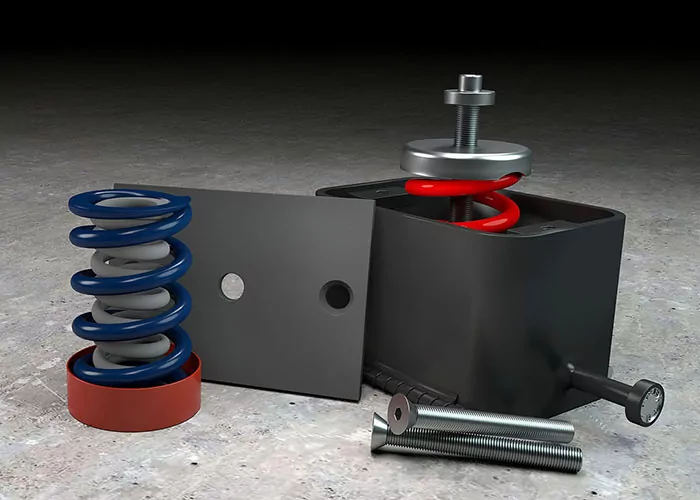

The LSM spring-isolated floor mount can be customized for a wide range of concrete slab thicknesses, air spaces, and/or loading options. Each LSM housing is fabricated to spec and includes nelson studs for rebar support, an internal spring isolator set in a neoprene cup, and lifting screws. LSM housings are spaced in a grid to support rebar for a concrete-isolated slab. Once concrete is poured and fully cured, the isolated slab is lifted by slowly turning the lifting screws to create the desired air space. Springs provide the lowest natural frequency of isolation and are proven effective for applications such as sensitive laboratories, weight lifting and exercise floors, or spaces adjacent to railways or other low-frequency noise sources.

LSM isolators are sold with project-specific shop drawings that detail the isolator layout, rebar, isolator performance and deflections, seismic restraint, and installation sequencing. Acousthetics offers an optional service to have the shop drawings fully engineered and signed/stamped by a state-licensed third-party structural engineer.